|

|

Is fuel efficiency really what we need most desperately?

I say that what we

really need is a car that can be shot when it breaks down.

Russell Baker

Solid oxide fuel

cells (SOFCs) are an important technology for efficient utilization of

hydrogen. Steam electrolyzers and ceramic membranes are closely related technologies

that can enable highly efficient production and utilization of hydrogen. SOFCs are

nearing commercial viability for some applications, but fundamental challenges remain,

especially reducing operating temperature and improving the stability and fuel flexibility

of the anode. Operating temperature is important not only for making the technology viable,

reducing the cost of high-temperature components, improving the stability of metallic

interconnects, and easing high-temperature seal issues, but for enabling new SOFC applications

such as transportation and portable generation. Anode alternatives to metallic Ni are needed to

improve stability during redox cycling and during electrolysis at high steam contents, and

for enabling highly efficient hydrogen production from natural gas

|

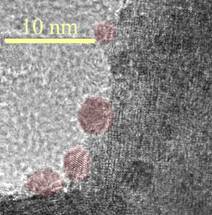

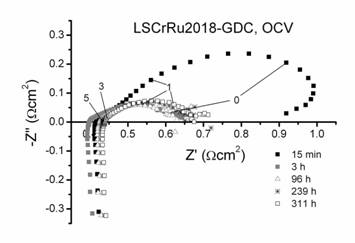

Figure 1.(a) High-resolution electron microscope image showing a portion of a La0.8Sr0.2Cr0.82Ru0.18O3

particle with Ru nano-clusters that nucleated upon reduction in H2

at 800C for 45 h. (b) Electrochemical impedance spectra obtained at various

times from a SOFC with LSCrRu-GDC anode at 800C, showing a rapid decrease in

polarization resistance that coincided with the nucleation of Ru

nano-clusters.

|

The basic premise of this project is that significantly enhanced electronic and ionic

transport properties of nano-scale oxides, combined with the high surface area

of nano-porous materials, offer an opportunity to address electrode

polarization and conductivity issues limiting low-temperature SOFC performance.

We have already developed new approaches to predict, characterize, and

understand low-temperature transport processes in new nano-scale materials that

are important for SOFCs. For instance. new fabrication methods have been

developed to produce nano-scale materials that are stable under low-temperature

SOFC conditions. Figure 1 illustrates a novel method that was developed for

producing nano-scale catalysts on SOFC anodes during operation, avoiding

coarsening that would normally occur during ceramic processing, and the

polarization resistance reduction that results. Given the obvious questions regarding

the stability of nano-materials, even at reduced SOFC operating temperatures,

nano-material stability is being studied both experimentally and by modeling.

Recent Publications

- Nucleation of nanometer-scale electrocatalyst particles in solid oxide fuel

cell anodes,

B.D. Madsen, W. Kobsiriphat, Y. Wang, L.D. Marks, and S.A. Barnett,

Journal of Power Sources 166, 64 (2007)

-

Electron microscopy study of novel Ru doped La0.8Sr0.2CrO3 as anode materials

for Solid Oxide Fuel Cells (SOFCs),

Y. Wang, B.D. Madsen, W. Kobsiriphat, S.A. Barnett, and L.D. Marks,

Microscopy and Microanalysis 13, 100 (2007)

- La0.8Sr0.2Cr1-xRuxO3-Gd0.1Ce0.9O1.95 Solid Oxide Fuel Cell Anodes: Ru Precipitation And Electrochemical

Performance,

W. Kobsiriphat, B. Madsen, Y. Wang, L.D. Marks, and S.A. Barnett,

Solid State Ionics, 180, 252, (2009)

|

Solid Oxide Fuel Cells

Solid Oxide Fuel Cells

Solid Oxide Fuel Cells

Solid Oxide Fuel Cells