Tad Williams

SPEAR

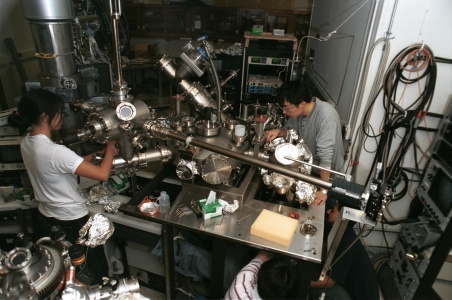

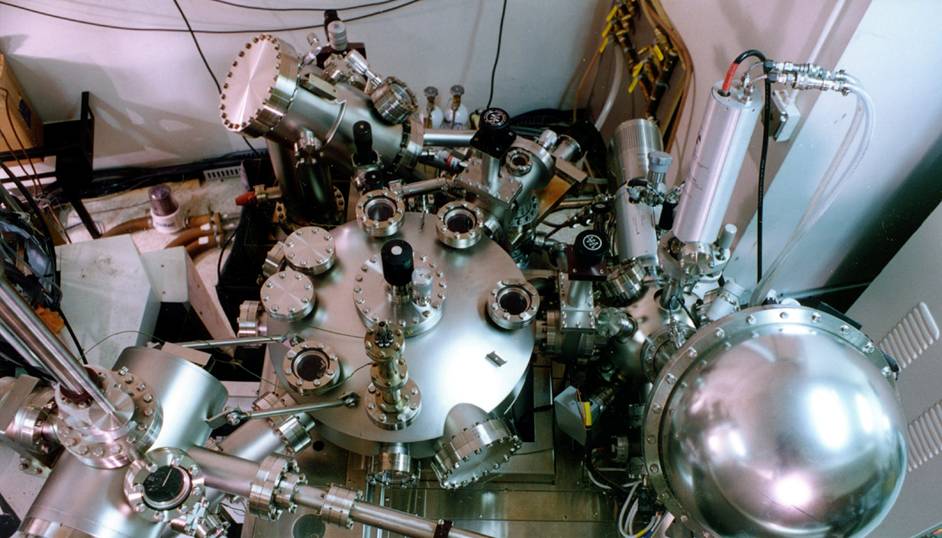

The Specimen Preparation Evaluation Analysis and Reaction System, or SPEAR, is a unique system of interconnected Ultrahigh Vacuum (UHV) chambers for the preparation, treatment and characterization of surfaces and interfaces. Transmission Electron Microscope (TEM) samples are transferred between the various chambers and the Hitachi UHV-H9000 high-resolution TEM, at all times in the mid 10-11 torr range. All sample manipulation is easily carried out from the outside.

SPEAR Components:

-

Load-Lock Chamber

This chamber is used for inserting and retrieving sample from SPEAR, without having to vent the whole system. Up to 5 different samples can be exchanged at a time. Once the chamber is loaded, it can be pumped from atmosphere down to 10-10 torr in roughly 8 hours.

-

Transfer Chamber

This is the central chamber, equipped with an extendable arm, mounted on a rotating carousel. This allows for easy transfer of samples to and from all other chambers. A separate section of the chamber allows for the loading of samples in special TEM cartridges, which can be subsequently inserted into the UHV-H9000 microscope. The transfer chamber can also store up to 11 individual samples.

-

Analytical Chamber

All characterization takes place here, with some of its capabilities listed here:

-

X-ray Source - This dual-anode source can be coupled to the hemispherical electron energy analyzer are used to obtain X-ray photoelectron spectra and thus gather surface-sensitive information about the composition of samples and element-specific chemical environment.

-

Ion Gun - A duoplasmatron ion source and an analog ion beam column capable of producing O, Ar or Xe ions with a maximum accelerating voltage of 10 kV. The gun can attain a probe size of less than 5 microns at a surface, which can be coupled with a secondary electron detector to generate topography-sensitive scanning electron micrographs during sputtering.

-

Hemispherical Capacitance Analyzer - It can acquire either XPS or AES spectra with high energy resolution, allowing for detection of shifts due to chemical bonding effects at the surface.

-

-

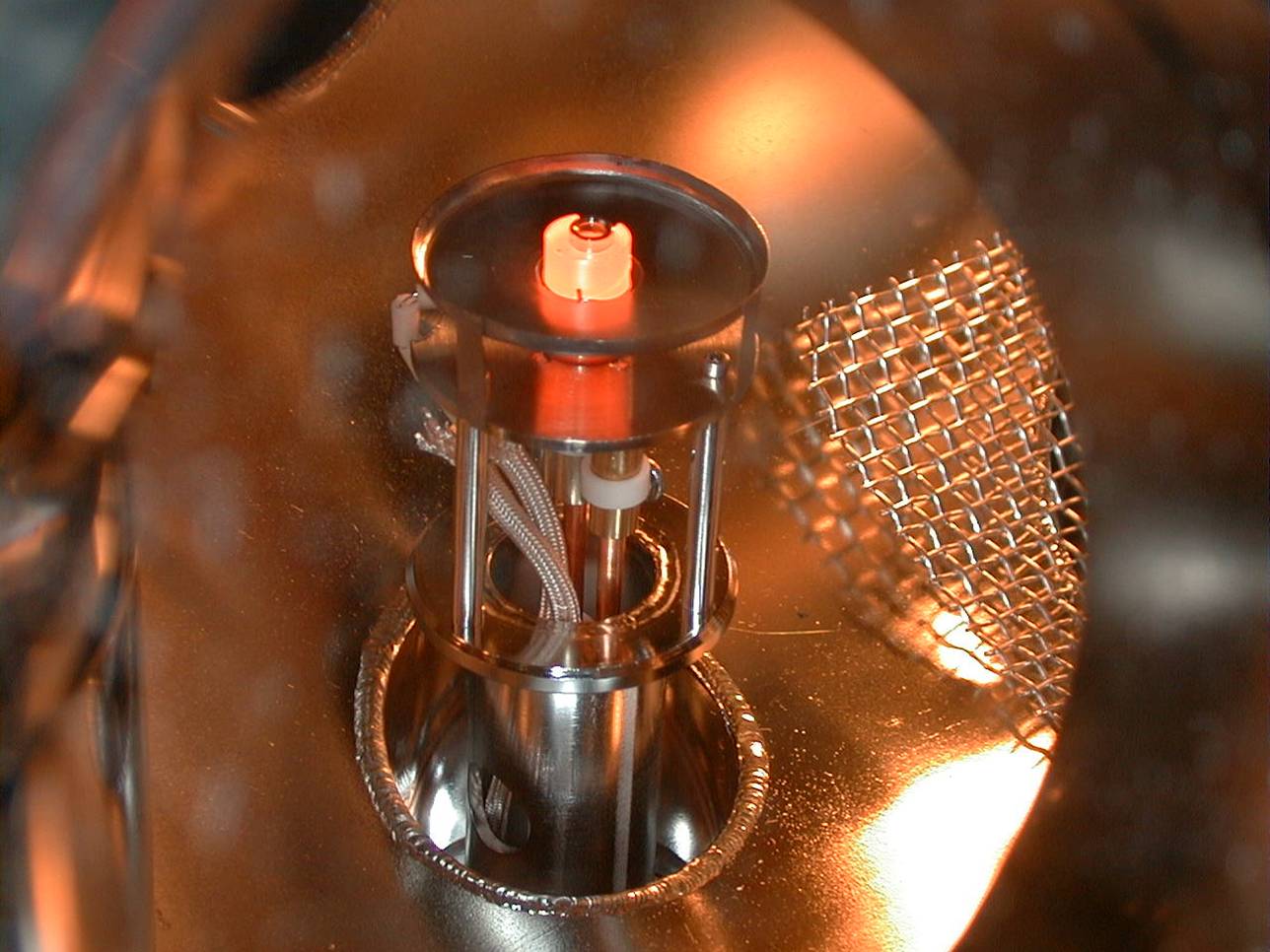

Gas Treatment Cell

This chamber contains two heating stages: one for UHV annealing at up to ~1000oC and another one for high pressure anneals. The latter can be hydraulically retracted into a small subchamber where one can heat samples under O, N or Ar gas flow.

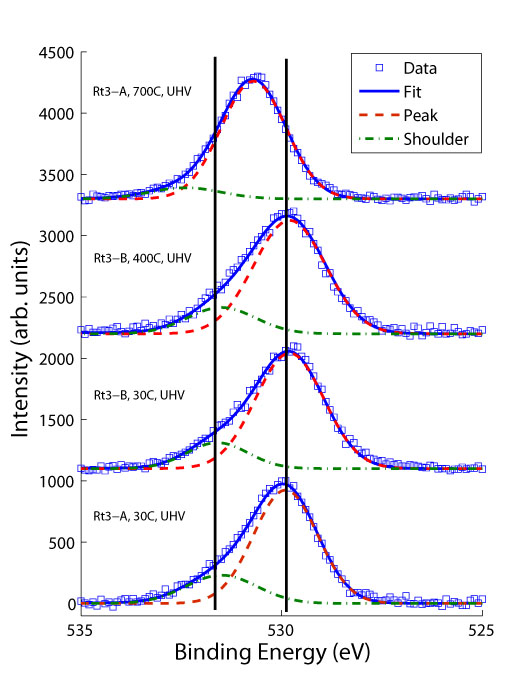

XPS data for MgO(111) samples after in-situ annealing at different temperatures. The peak shoulder is related to the adsorption of hydroxyl groups. PRB 79, 085421 (2009).