Chinese Proverb

Tribology

The phenomena associated with surfaces in contact and relative motion form the basis for tribological research. The importance of controlling friction and wear through structure, materials selection and lubrication was realized since the time of the construction of the pyramids. Despite this, only a fragmented understanding of the fundamental mechanisms of friction exists.

In the modern world, energy losses by friction have been estimated to represent an economic cost of $100 billion dollars annually in the U.S. alone. Up to $21,000,000,000 (1981 U.S. dollars) could realistically

be saved through efficiency improvements resulting from tribological research. This massive economic driving force plays a large role in the development of alternative fuels and energies, including the design of new materials with favorable friction and wear properties.

We need to understand the fundamental materials science relationship between structure and properties at all size scales, ranging from atomic through nanoscale to the micro and macro scales. It is only when we have this information that it will become possible to make revolutionary rather than incremental improvements. For tribology we do not yet understand enough about the materials science of weak sliding interfaces, and this is precisely what is needed so we can optimize the performance.

There are three fundamental reasons why we do not understand weak interfaces:

-

Almost all the materials science of interfaces has been targeted towards harder, stronger, and lighter structural materials, concentrated on strong interfaces; if the interface was weak this was considered to be of minimal interest and ignored.

-

With very few exceptions the fundamental materials science of mechanical properties (dislocation motion, work hardening, precipitate effects, creep and grain size effects to name just a few) has only been developed for strong materials, and the extent to which the models work for weak interfaces is relatively unexplored.

- There has not been much development of imaging tools to understand in detail what is taking place at the nano to micro scale at a sliding interface. For instance, we know most of the basic nanoscale processes taking place during mechanical deformation of materials based largely on in-situ TEM experiments performed more than thirty years ago; there are almost no comparable in-situ experiments which have imaged nanoscale processes during sliding.

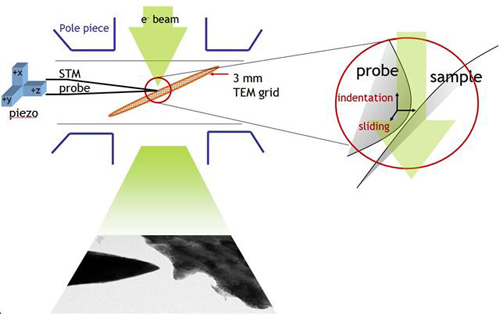

We use both experimentand theory to establish some of the basic materials science of weak interfaces important in tribology. The experimental component exploits an in-situ holder which allows us to observe samples during tribologically relevant experiments in a transmission electron microscope, monitoring nanoscale structural and chemical changes in real time. The theoretical component exploits some of the existing materials science models which are known to work well for strong interfaces to the case of weak interfaces, and from this attempt to extract general models.

Currently, our tribology in-situ work is performed at Argone National Laboratory Electron Microscopy Center. The in-situ holders have also been used at other national labs across the country for specialized TEM experiments.

Related Presentations and Videos:

Tribology

Recent Publications

-

The effect of contact load on CoCrMo wear and the formation and retention of tribofilms

M.A. Wimmer, M.P. Laurent, M.T. Mathew, C. Nagelli, Y. Liao, L.D. Marks, J.J. Jacobs and A. Fischer

Wear, 2015. 332333(0): p. 643-649

-

Nanoscale Abrasive Wear of CoCrMo in In Situ TEM Sliding

Liao, Y., E. Hoffman, and L.D. Marks

Tribology Letters, 2015. 57(3)

-

Tribochemical Reactions in Metal-on-Metal Hip Joints Influence Wear and Corrosion

Wimmer, M. A., Mathew, M. T., Laurent, M. P., Nagelli, C., Liao, Y., Marks, L. D., Pourzal, R., Fischer, A., Jacobs, J. J.

ASTM Selected Technical Papers 2013, DOI:10.1520/STP156020120050.

-

Direct Observation of Tribochemically Assisted Wear

A. M'ndange-Pfupfu, J. Ciston, O. Eryilmaz, A. Erdemir, and L.D. Marks

Tribology Letters, 49 (2013) 351.

-

CoCrMo metal-on-metal hip replacements

Y. Liao, E. Hoffman, M.A. Wimmer, A. Fischer, J.J. Jacobs, and L.D. Marks

Physical Chemistry and Chemical Physics. , 15 (2013) 746.

-

New insights into hard phases of CoCrMo metal-on-metal hip replacements

Y. Liao, R. Pourzala, P. Stemmera, M. A. Wimmerc, J. J. Jacobsa, A. Fischerb, L. D. Marks

Journal of the Mechanical Behavior of Biomedical Materials 12 (2012) 39

-

Modeling of Phonon Wind Shielding Effects on Moving Dislocation Arrays

M'ndange-Pfupfu, A. and L.D. Marks

Tribology Letters, 47 (2012) 431.

-

Graphitic Tribological Layers in Metal-on-Metal Hip Replacements (Supporting Info)

Y. Liao, R. Pourzal, M. A. Wimmer, J. J. Jacobs, A. Fischer and L. D. Marks

Science 334 (2011) 1687

-

Quantification of sliding-induced phase transformation in N3FC diamond-like carbon films

A. M'ndange-Pfupfu, O. Eryilmaz, A. Erdemir, and L.D. Marks

Diamond and Related Materials 20 (2011) 1143

-

Direct observation of tribological recrystallization

Y. Liao, S.K. EswaraMoorthy and L.D. Marks

Philosophical Magazine Letters 90 (2010) 219.

-

Temperature activated self-lubrication in CrN/Mo2N nanolayer coatings

R. A. Koshy, M. E. Graham, L. D. Marks

Surface & Coatings Technology 204 (2010) 1359.

-

In situ TEM studies of tribo-induced bonding modifications in near-frictionless carbon films

A.P. Merkle, A. Erdemir, O.L. Eryilmaz, J.A. Johnson, L. D. Marks

Carbon 48 (2010), 587.

-

Modeling of Thermal-Assisted Dislocation Friction

Y. Liao, L. D. Marks

Tribology Letters 37 (2010) 283.

-

A Dislocation-Based Analytical Model for the Nanoscale Processes of Shear and Plowing Friction

A. M'ndange-Pfupfu and L.D. Marks

Tribology Letters 39(2010) 163.